Tungsten Carbide Plate for VSI

Basic Info.

| Equipment | Vertical Impact Crusher |

| Bending Strength | 1700 Trs N/mm² |

| Compositions | Wc94%+Co6% |

| Density | 14.80g/Cm³ |

| Main Material | Tungsten Carbide Yg6 |

| Transport Package | Standard Export Carton |

| Specification | Custom Service Available |

| Trademark | Miller ™ |

| Origin | Zhuzhou, China |

Product Description

Product Description

Tungsten Carbide strips and bars for Ore Crushing Machine, in another way sand making machine wear block, belongs to the core part of the vertical impact crusher (sand making machine). crusher hammer are equipped with tungsten carbide stripes that protects the rotor of the VSI crusher against wear, mainly used for breaking stone into sand,also widely used in mines, sand, cement, metallurgy, hydropower engineering , ore processing and other industries with its strong wear resistance …

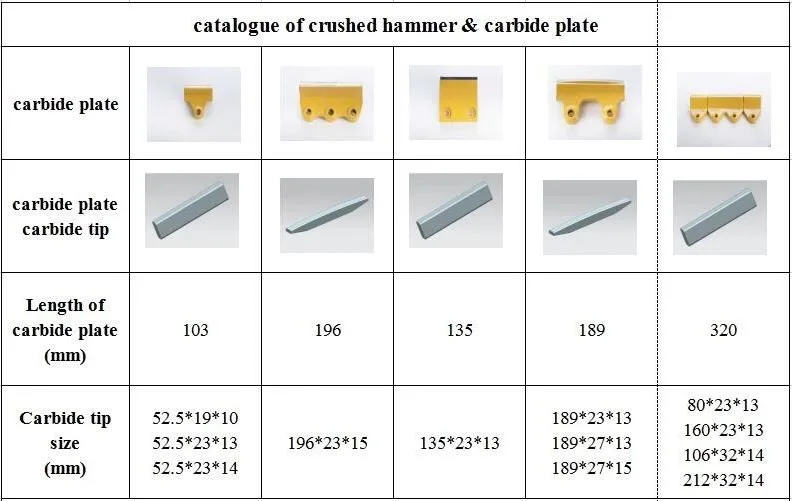

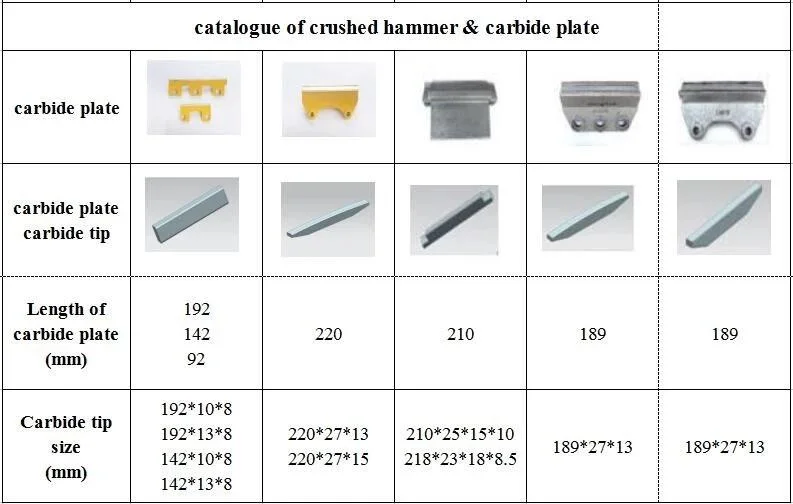

Specification

| Other Names | Tungsten Carbide Strips and Bars |

| Material | Tungsten carbide, hard metal, hard alloy, tungsten steel |

| Features,Advantages | HIP sintering, wear resistance,good impact resistance,high bending strength,high bonding strength. |

| Size Ranges | Length≤900mm, Width≤550mm, Thickness≤140mm |

| VSI Rotor Tips Types | Flat bar, bar with arc |

| Brand | Miller ™ |

| Size Customizing Service | Available |

| Applications(Equipment) | For vertical impact crusher(sand making machine) |

| Applications(Use for ) | It is widely used in mines, sand, cement, metallurgy, hydropower engineering , ore processing and other industries with its strong wear resistance .. |

Detailed Photos

Packaging

Company Profile

Miller Carbide is an experienced manufacturer of tungsten carbide customized parts started from 2008. Our products cover carbide grinding jars & bowls & mortars, carbide grinding balls, carbide pegs, carbide static & dynamic rings, bead mill disks, carbide stirring rods, carbide static & dynamic jaws, carbide crusher plates, carbide grinding discs, carbide rotors, carbide roll rings, carbide guide rolls, carbide burrs, carbide sleeves & bushings, and other customized wear-resistant components for valve and pumps ect. With years of tungsten carbide engineering and manufacturing experience, we can concentrate our skills to the development of customized products for a wide spread of wear applications in milling & crushing industry.

Unlike other suppliers, Miller operates with three disciplines: Engineering, manufacturing and after sale service support. This means we are able to improve the efficiency of your machine and tools with customized products and direct access to the manufacturer. Miller Carbide works closely with its customers to ensure their requirements are designed efficiently and suitable for application. We can design the components needed from drawings or delivered samples. We adhere to the management principles of "quality first, customer first and credit-based" since the establishment of the company and always do our best to satisfy potential needs of our customers. We are sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with an irresistible force.Company Advantage

We Offer You These| Direct Sales Integrating R&D, production sales and technology | Mold customizationRich moldsOEM customization accepted | Adequate equipment grinding/pressing sintering/deep processing | Technical strength15 years of experience in technical team, research & innovation |

FAQ

1. How long is your delivery time?We can arrange the shipment within 3-5 working days upon receipt of your payment for any sintered blanks stocked items. As for the mass production order or the customized products, we will need 10-30 days production leadtime and indicate the delivery time on the Proforma lnvoice. 2. Can l get a sample from you for Quality checking? Is it free of charge or need pay ?Yes, we can offer the sample for free of charge with freight collected if we have in stock.If the sample is special or non-standard shaped, we will charge you only the basic production costs accordingly. 3. What's grade should I choose for the product?If you have no idea about the grade, please kind to provide the information of the usage of the product, our technical team will suggest the most suitable grade for you.4. Do you use recycle materials?We insist on quality come first, all the products are made of virgin raw materials. 5. Can you make the goods according to my sample or drawing ? What's your (MOQ) minimum order quantity? Yes, We have a group of experienced technical personnel, advanced mould production equipments. Our R&D teams were graduated from University, and our technical R&D team lead by Doctors of Powder Metallurgy and Professors.

For the customized item we quote the MOQ individual; For the standard items in stock, we have no limitation on the MOQ . 6. Can I negotiate the Prices?Yes, we can consider the discount for bulk orders. 7. Can you give warranty of your products?Yes, we can give you 100% satisfaction guarantee on all items. We have the independent inspection department with the completeadvanced product quality testing instrumentation to carry out IQC, PQC, FOC, and the detailed inspection pictures and testing report will be available and sent to you for confirmation before delivery.In case there was any quality problem, just please kindly to provide the pictures to show the problem by email. We should be 100% responsible for our problems and provide you the replacements at our costs.

Contact us now! Get your free quote!