Category

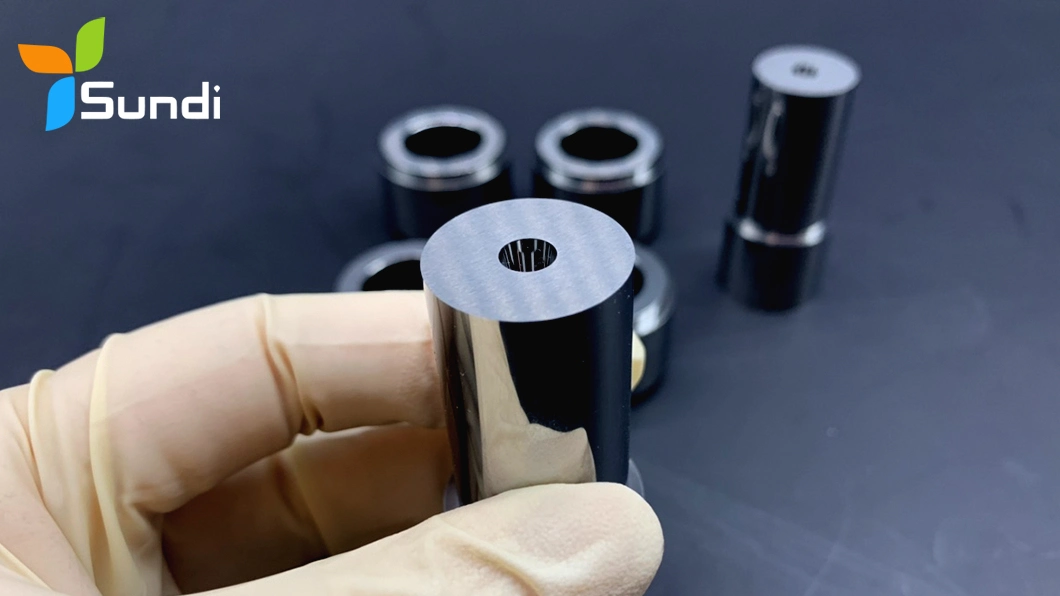

OEM Mirror Polished Dlc Mold Components Fabricate Tungsten Carbide Cemented Forming Metal Stamping Tools Punches and Dies

Overview Package Size 19.00cm * 19.00cm * 10.00cm Package Gross Weight 1.000kg Company Profile Product Description Our A

Overview

Company Profile

Our Advantages

Of course, we also take the design for clients and make the special parts and mold, satisfied with customers of high quality.

HOW ABOUT THE LEAD TIME?

The lead time is based on the quantity and complexity of the ordering tools. it's normal for 10-20 days, If urgent,

we'll arrange the production with top priority to reduce lead time.

DO YOU KEEP A STOCK OF YOUR PRODUCTS?

We will stock for the regular ordering parts, for the customized product we need to machine them according

to special requirements.

CAN YOUR ENGINEER JOIN OUR PROGRAM DESIGN

We're very pleased to be working with you, we can offer our idea and design.

IS THERE A PRICE LIST?

Feel free to contact our sales to get the last price list and offer.

Basic Info.

| Model NO. | B0140005 |

| Material | Carbide |

| Application | Electronic, Hardware, Machinery, Car, High Speed Press Stamping |

| Certification | ISO9001:2015 |

| Tolerance | +/-0.002mm |

| Surface Finish | 0.3-0.4 Micron |

| Carbide Source | Everloy,Fujilloy,Ceratizit,Kenna |

| Transport Package | Cartons or Wooden |

| Trademark | SUNDI |

| Origin | Wuxi China |

| HS Code | 8207300090 |

| Production Capacity | 50000/PCS Year |

Packaging & Delivery

Package Size 19.00cm * 19.00cm * 10.00cm Package Gross Weight 1.000kgProduct Description

Company Profile

| Part Name | Custmized forming punch,punch and die ,die components |

| Manufacturing process | Machining Center/CNC lathes/Surface Grinding machines/Milling Machines/Wire-cuts/CNC bearing Machines/ Cylindrical Grinding Machines/ Profile Grinding,E.D.M machines/Etc . |

| Materials: | Tungsten Carbide:F10,H40S,H25S,G4,KD20/etc |

| ASSAB :ASP23,XW42,EM2,718HH/etc Japanese:HPM2,NAK80,SKD61,SKS3,SKD11,DC53,SKH51/etc SCHMOLD:1.2379,1.3343,1.2990 | |

| Surface Treatment | Blacking/Chrome/Zincplating/DLC/TICN/Oxidation Treatment. |

| QC | 100% inspection before delivery |

| Payment | 30% in advance,70% before shipment.Samples 100% with order |

Of course, we also take the design for clients and make the special parts and mold, satisfied with customers of high quality.

HOW ABOUT THE LEAD TIME?

The lead time is based on the quantity and complexity of the ordering tools. it's normal for 10-20 days, If urgent,

we'll arrange the production with top priority to reduce lead time.

DO YOU KEEP A STOCK OF YOUR PRODUCTS?

We will stock for the regular ordering parts, for the customized product we need to machine them according

to special requirements.

CAN YOUR ENGINEER JOIN OUR PROGRAM DESIGN

We're very pleased to be working with you, we can offer our idea and design.

IS THERE A PRICE LIST?

Feel free to contact our sales to get the last price list and offer.